As a leader in food processing equipment, Lyco’s focus is on improving customer’s ROI through innovative designs.

Lyco’s Clean-Flow® Continuous Blancher is State of the Art in a variety of ways.

The Clean-Flow® Continuous Blancher also features a new sanitary Slide-Out and Discharge Chute

Clean flow

Lyco’s Clean-Flow® Continuous Blancher w/ Hydro-Flow® Technology

- Revolutionary for Pasta, Rice, and Vegetable Processing

- Totally eliminates losses from sticking and clumping

- Flexibility – change over from one product to another in minutes, many times a day

Benefits

- Hydro-Flow = uniform quality

- Higher recovery (5-15%)!

- Damage and clumping. Losses are <1.0%

- High production rates:

up to 15,000 PPH (6800 Kg/H) of Dry Beans

up to 10,000 PPH (4500 Kg/H) of Pasta

up to 10,000 PPH (4500 Kg/H) of Rice

Pasta Blancher

Advantance – Capacity Rotary Blancher Sizing–50 lbs/cubic ft. (800 Kg/m3)

Quick-Change Over

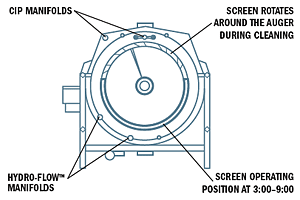

Clean-Flow Screen rests in the 3:00–9:00 position for operation, and rotates 360 degrees during the cleaning process, depositing residue in thetank for disposal in mere minutes.

- CIP in 15 Minutes

- Space Savings

- High Recovery (5-15%)

- Patent Pending

Supplemental Information

A case study of Clean-Flow™ in action at Brake Bros Food Service