Infeed & de-watering

Step 1Gentle infeed, screening and water removal to stabilize flow and protect product.

- Stabilize upstream hopper levels and line pace

- Screen fines; remove free water to reduce carryover

Packaging and processing systems for pasta, rice, beans, vegetables, meats and more—selected for reliability, total cost of ownership, and afterservice availability.

Start with key families below—open a card for highlights and typical use cases. Detailed specs available on request.

High‑volume chub packaging with continuous operation, flexible sealing and material savings.

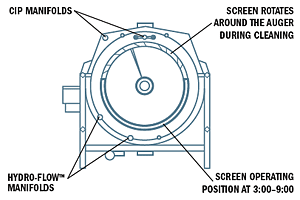

Innovative blanching with Hydro‑Flow® agitation for uniform quality, higher recovery and rapid changeovers.

Space‑efficient continuous systems with sanitation benefits and energy efficiency.

Customized blending, cooking and material‑handling modules for upstream and mid‑process.

High‑volume, continuous chub packaging with flexible sealing options, tight diameter control and recipe‑driven changeovers.

Suitable for a wide range of pumpable products.

Highlights that affect throughput, cost and usability.

Features | Benefits |

|---|---|

| 1 CE marked | Fulfills global safety requirements |

| 2 Close-clip options | Reduced film costs; enhances package aesthetics |

| 3 Continuous motion | Reduces downtime and parts usage |

| 4 Clutch brake option | Flexibility to fill long packages |

| 5 Explosion-proof motors & pressurized cabinet (opt.) | Safe in hazardous environments; lower risk & insurance premiums |

| 6 Graphic readout of operating conditions | Ease of operator interface |

| 7 Heavy-duty, high-speed clipping head | Increases productivity & reliability; up to 120 ppm |

| 8 KwikTear | Consumer-friendly package |

| 9 Multiple date-coding options | Flexibility in choosing coder |

| 10 Multiple film sealing systems | Heat, RF, extrusion sealing |

| 11 PLC control | Visual display, store recipes, faster start-up & changeover, multi-language |

| 12 Registration | Run pre-printed film; no label required |

| 13 Rollstock clips & film | Save ~60–80% vs pre-formed clips |

| 14 Simplified clipping head assembly | Reduces parts/service costs; prevents damage |

| 15 Simplified film handling | Easier loading/threading; less down-time; less training |

| 16 Simultaneous adjust (clip/film/pump) | Quick changeover; reduces scrap |

| 17 Stainless steel construction | Made for rigorous wash-down |

| 18 Under-carriage with overload | Reduces maintenance costs |

| 19 Voider system | Reduces waste; tighter clips; improved appearance |

| 20 2nd package registration | Eliminates film waste; saves set-up time |

| 21 Three sealing options | Heat · RF · Extruder |

| 22 40+ ppm with clutch brake | Handles extended/second-third registration |

Headline specifications for common models.

Description | 2500 | 4000 | 4100 |

|---|---|---|---|

| PPM Min/Max | 15–120 | 15–120 | 15–150 |

| Machine Control | PLC | PLC | PanelView (touch) |

| Available Seal Methods | Heated Air · RF · Extrusion | Heated Air · RF · Extrusion | Heated Air · RF |

| Diameter Range * | — | 5/8″ – 4 1/8″ | 5/8″ – 4 1/8″ |

| Std. Length Range ** | 4″ – 12″ | 4″ – 12″ | 4″ – 12″ |

| Maximum Film Sealing Speed *** | — | 1200 inches/min | 1200 inches/min |

Gentle infeed, screening and water removal to stabilize flow and protect product.

Clean-Flow® or rotary drum systems optimize heat transfer and uniformity.

Rapid cooling locks texture and stops cook; separation removes starch and fines.

Product handling to packaging with optional QA gates.

KartridgPak chubmaker or cartoning; date-coding integrated via Elmoprint.

Recipe control, OEE visibility and integration to plant systems.